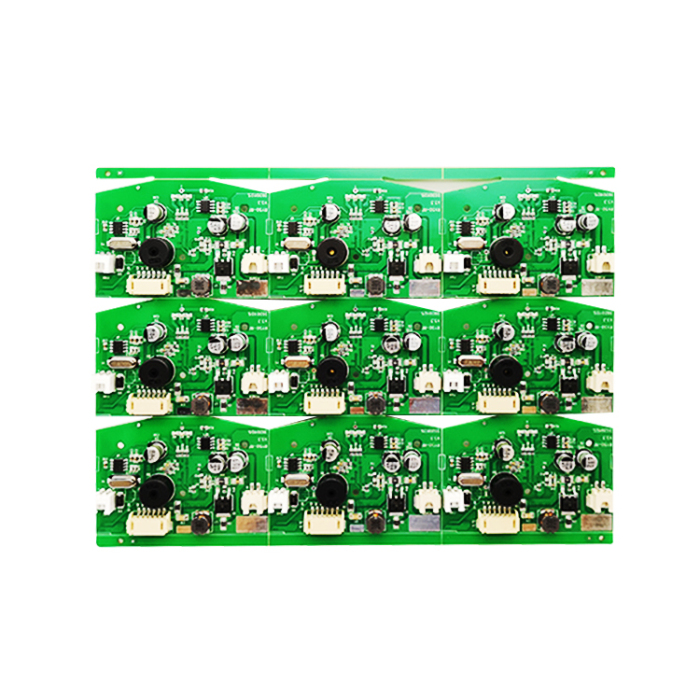

Electronic Products Multilayer PCB Assembly

Basic Info

Model No.: Electronic Assembly

Product Description

Where are the through hole PCB assemblies used?

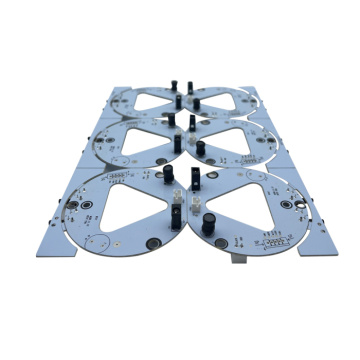

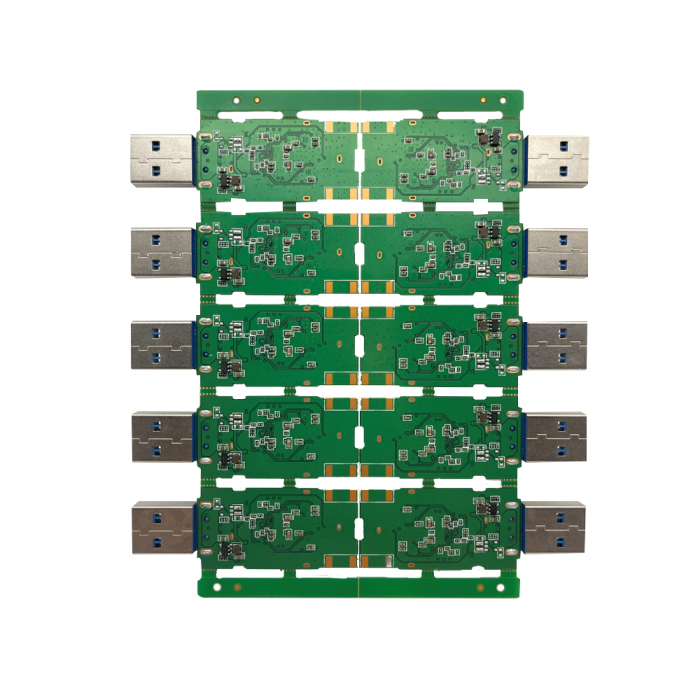

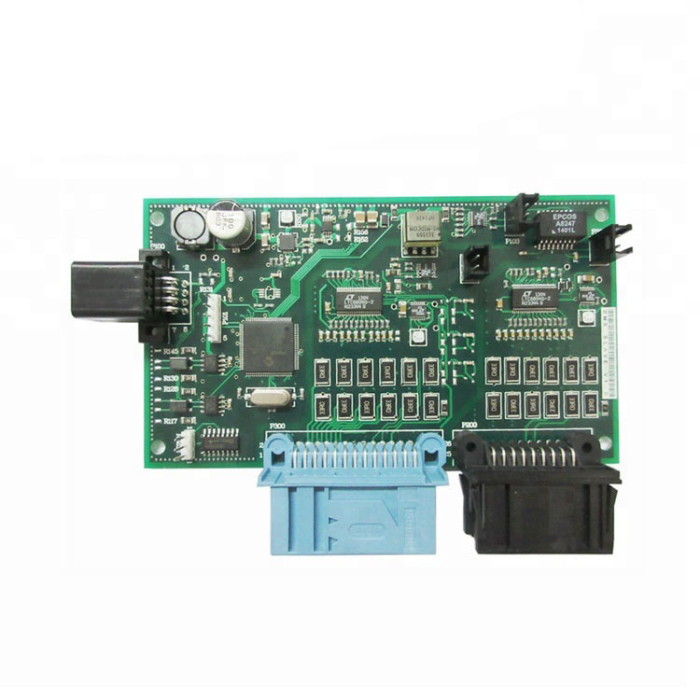

As the demand for advanced and miniature products grows, so does the printed circuit board (PCB) industry. Today, PCBs have become smaller than before. Due to its small surface, mounting various components on the circuit board is challenging. To alleviate this situation, manufacturers are using two techniques to mount electrical components on circuit boards. These technologies are plated through-hole Assembly technology (PTH) and surface mount technology (SMT). PTH is one of the most common technologies used to mount electronic components (including microchips, Electronic Resistor and Capacitor and Electronic connectors) onto circuit boards. In the through-hole assembly, the leads pass through the pre-drilled holes to form a cross-shaped pattern on the other side.

PTH components are called "through holes" because the leads are inserted through copper-plated holes in the circuit board. These components have two types of leads: axial leads and radial leads.

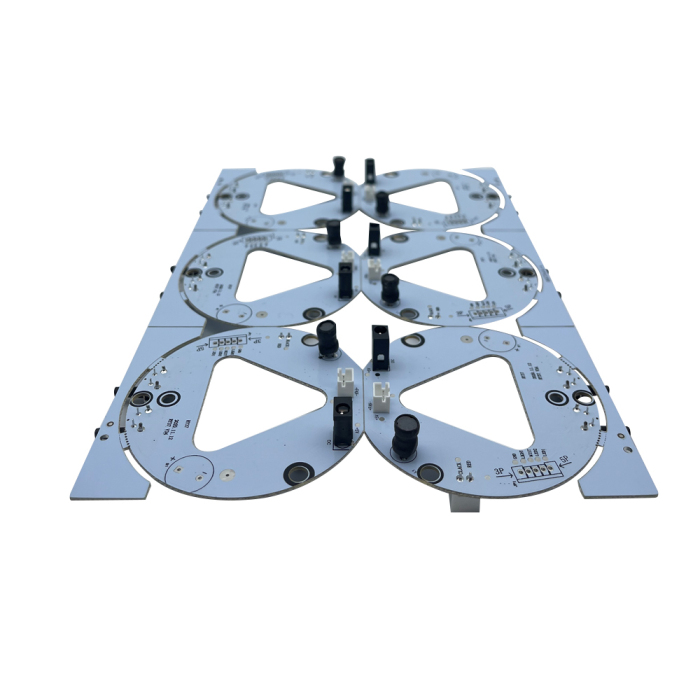

Axial Lead Components (ALC): These components may have one or more leads. Lead the lead from one end of the component. During the plated through-hole assembly process, both ends pass through individual holes on the circuit board. Therefore, the components are placed tightly on the circuit board. Electrolytic capacitors, Fuses, light emitting diodes (LEDs) and carbon resistors are some examples of axial components. When manufacturers are looking for a compact fit, these components are the first choice.

Radial Leaded Components (RLC): The leads of these components extend out of their body. Radial leads are mainly used on high-density boards because they take up less space on the circuit board. Ceramic disc capacitors are one of the important types of radial lead components.

4 reasons to use plated through-hole components in the PCB manufacturing process

Through-hole technology has various advantages, which helps its popularity among electronics manufacturers.

Simple prototyping: plated through-hole technology can achieve faster prototyping than SMT. The pin through-hole component can be soldered to the board by hand soldering or wave soldering. In addition, you can even evaluate the board design before making the board.

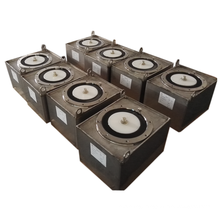

Excellent physical connection: PTH helps to establish a strong mechanical bond between the component and the circuit board. This technology is used to install components that must withstand mechanical stress, high power and High voltage, such as connectors, transformers, capacitors, and semiconductors.

High power tolerance: Through-hole components can easily meet high power requirements. Through-hole components work with circuit boards, and they can easily withstand mechanical and environmental pressures. This is why through-hole components are widely used in aerospace and Military electronic products that need to withstand high temperatures and regular acceleration.

Component durability: As we all know, through-hole mounting helps to establish a strong physical bond between components. These components are firmly soldered on both sides of the circuit board, helping to improve its durability.

Product Categories : PCB Assembly Products > Through-Hole Assembly